NGHI QUAN

PRODUCTION AND TRADING CO., LTD

0909 470 880 - 0914 085 322

0909 470 880

What is aluminum sheet?

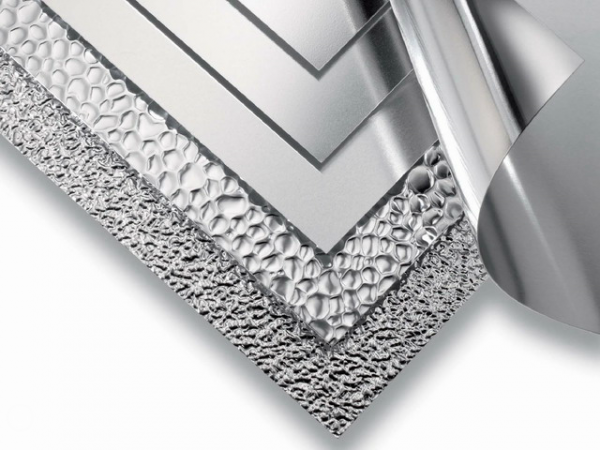

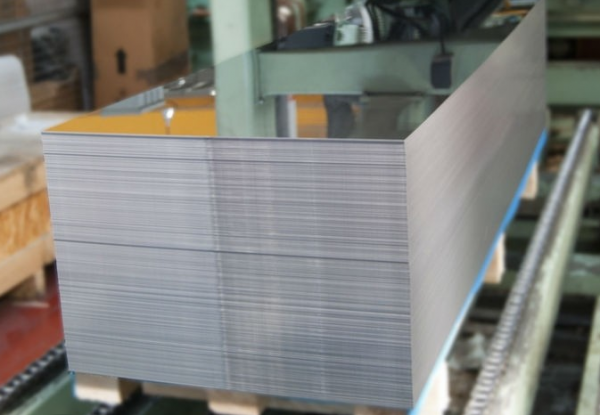

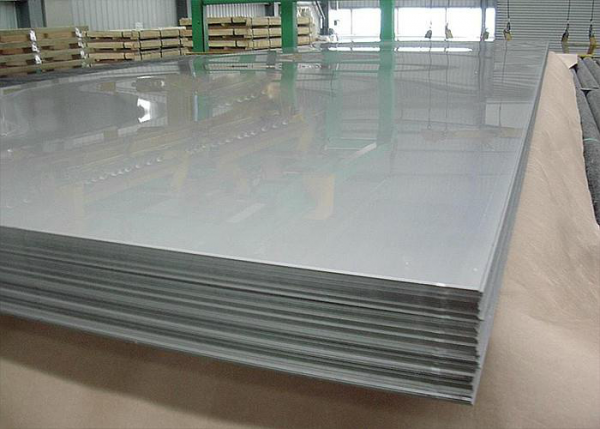

Aluminum sheets are pieces of aluminum that are formed in sheets with different sizes depending on the needs of use and production. Aluminum sheet has extremely strong structure of element Al and aluminum oxide film extremely durable; when they link together, they will have a silvery white that is very eye-catching and recognizable; Has good moisture resistance and extremely high corrosion resistance. Because of the good properties, aluminum sheet is widely used in manufacturing, civil, mechanical, ...

Characteristics and aluminum plate products

The characteristics of aluminum sheet are as follows:

Some of the aluminum sheet products are as follows:

Application of aluminum plate

Prior to these good properties, aluminum sheet was applied in the following areas:

At Nghi Quan, quality is guaranteed to match customers’ expectations.

We always try to improve our customer service.

This is the foundation for our development.

Add: 158 Van Than Street, Ward 8, District 6, HCMC VIETNAM

Showroom: 139A Van Than Street, Ward 8, District 6, HCMC VIETNAM

Manufacturing Plant: F4-F5-F23, Street 6, Area TT, Le Minh Xuan Industrial Zone, Tan Nhut Comune, Binh Chanh District, HCMC VIETNAM

Email: nghiquan2009@gmail.com

Phone: (+84) 909 470 880; (+84) 914 085 322

Website: www.nghiquan.com